Essential Guide to Understanding Machining Tolerances in Manufacturing

Discover essential insights on machining tolerances in manufacturing. Learn how to achieve precision and quality in your projects. Read the article now.

In this article, we explore the unique requirements of the medical industry, the importance of process and material selection, and the critical role of advanced technology in precision medical fabrication.

In medical device manufacturing, the highest quality, safety, and efficacy standards are non-negotiable. You need a precision assembly process that seamlessly integrates.

This article explores the advantages of full-service metal assembly over traditional methods, highlighting its benefits and integration strategies for your projects.

Explore the role that precision metal fabrication plays in the aerospace sector, the stringent industry standards and regulations that govern manufacturing, and showcase how precision metal fabrication is shaping the future of the aerospace industry.

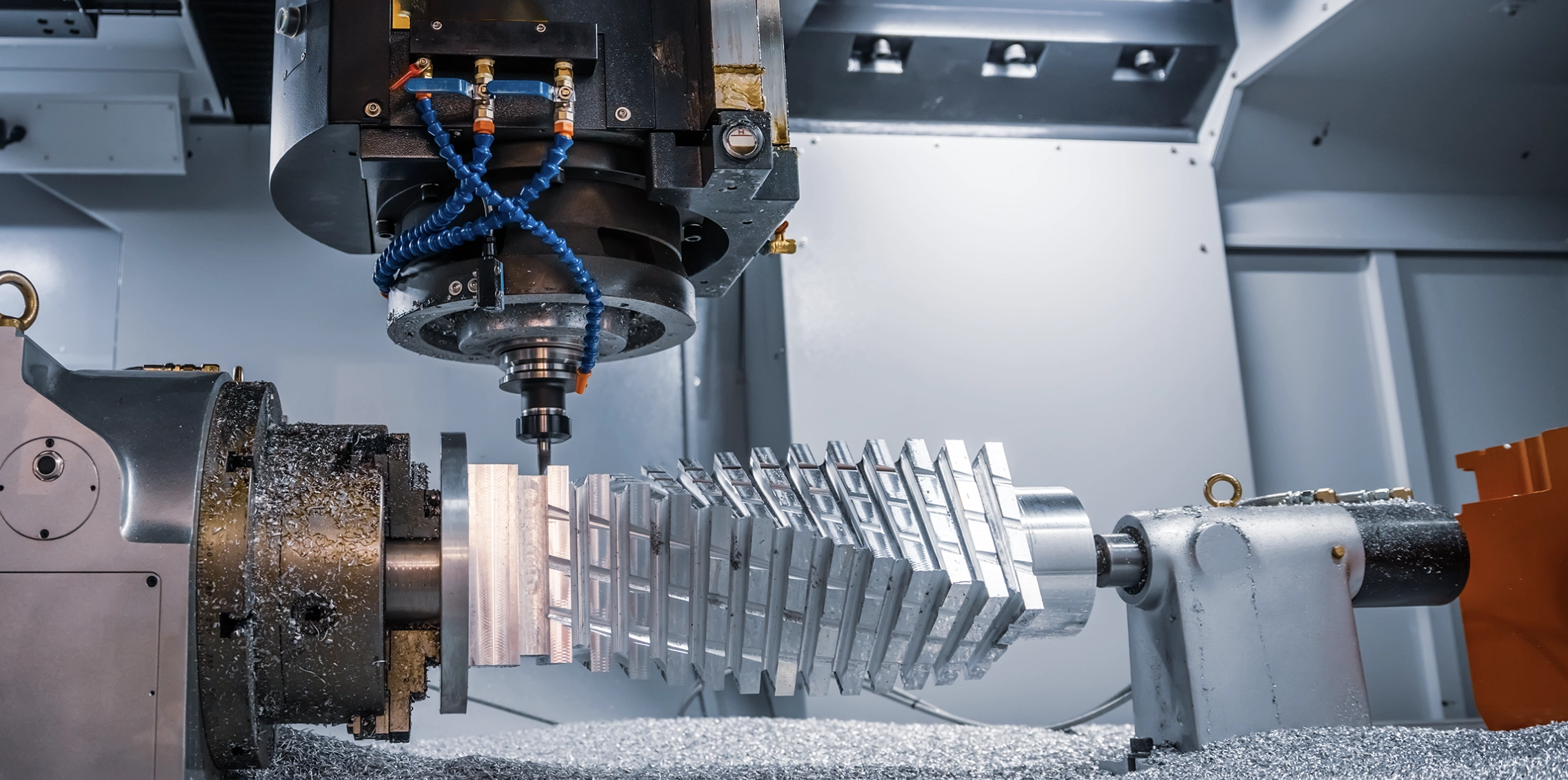

In this article, we break down what 5-axis CNC machining is, how it works, and the remarkable advantages this high-speed machining brings to leading industries right across the globe.

Southern California’s metal fabrication leader invests in high productivity and capacity machining and turning centers

Let’s explore the pillars of a streamlined assembly process and how cutting-edge tools and technologies can elevate your sheet metal components to unmatched levels of precision and reliability.

Precision sheet metal forming is paramount in today's leading industries. At Pinnacle Precision, we specialize in transforming raw metal sheets into sophisticated components that fuel innovation for our customers in the defense, medical, communications, aerospace, and renewable energy industries.

Different metal finishing techniques have unique advantages and applications, with painting being versatile and visually appealing, powder coating providing exceptional durability and eco-friendliness, and silk screening allowing for intricate and detailed designs.

Explore the benefits of local metal fabrication in our latest post, highlighting improved communication, faster delivery, and quality work from firms like Pinnacle Precision.

Selecting a reliable metal fabrication partner is crucial for project success.

Delivering durable and dependable parts for the aerospace industry demands precision manufacturing. Pinnacle Precision is ready to deliver.

Pinnacle Precision launches a complete corporate rebrand and sets a new course as a precision metal solutions provider.

Pinnacle specializes in CNC machining for precision, efficiency, and scalability.

Pinnacle Precision is celebrating 50 years of success. It’s been a great run, and our future is bright.

The entire Pinnacle crew came together to deliver the components needed for life-saving ventilators during the COVID-19 pandemic.