delivering precision to the

Medical Industry

The technical, manufacturing, finishing, and quality assurance expertise at Pinnacle Precision is on full display while delivering precision metal components used by leading medical instrument suppliers. Our decades of experience working with medical-grade alloys and finishes gives our customers confidence while they build ventilators, scientific instruments, and cabinets that house sensitive life-saving technologies. Likewise, Pinnacle’s assembly team saves customers time and money by installing hardware and sealants. Our quality assurance pros ensure parts adhere to the most stringent requirements to keep medical professionals and patients healthy.

delivering precision to the

Aerospace Industry

Pinnacle is an AS9100-certified manufacturer of precision metal components used in the aerospace industry. To earn the AS9100 certification, Pinnacle’s team met stringent manufacturing and quality management standards developed by the Society of Automotive Engineers and stands ready to support aerospace customers’ needs. Pinnacle leverages its decades of experience to deliver precision components for applications from cabin to cargo. We have expertise working with aerospace-grade alloys, finishes, and hardening requirements to support leading aerospace manufacturers.

delivering precision to the

Defense Industry

Delivering mission-critical parts, components, and assemblies to manufacturers in the defense industry is an honor and privilege for Pinnacle’s team of engineers, fabricators, and quality assurance professionals. Pinnacle is an AS9100-certified manufacturer, meaning our facility meets stringent manufacturing and quality management standards. We are ready, willing, and able to do our part for defense customers.

delivering precision to the

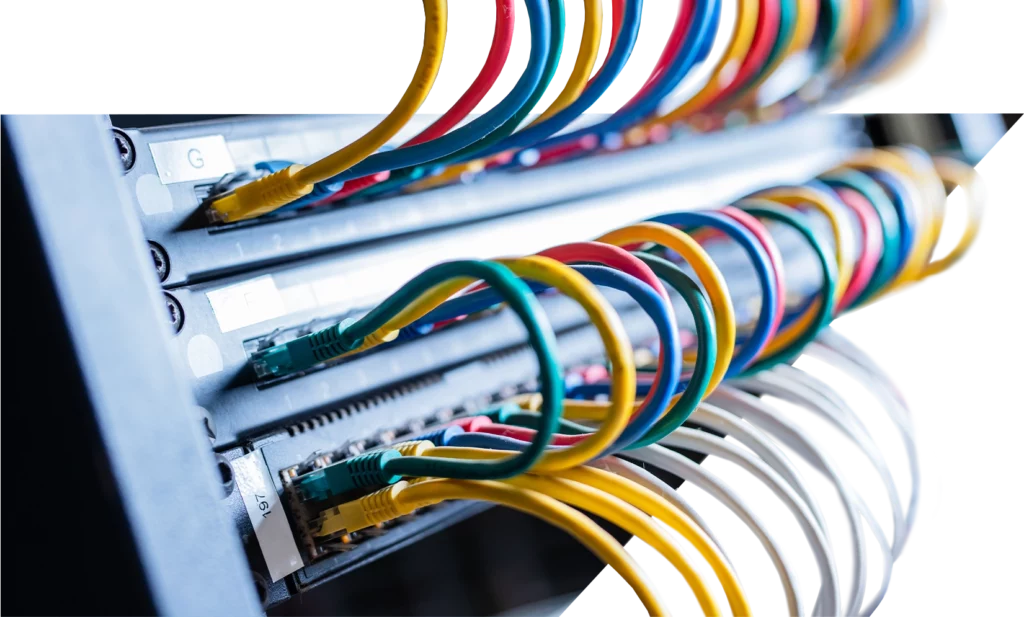

Communications, Technology, & Information Industry

Delivering precision metal components used by leading communications, technology & information customers leverages every capability at Pinnacle Precision. Our manufacturing, finishing, and quality assurance experts have a hand in delivering commercial-grade ICT enclosures and server racks used in auditoriums, stadiums, and Fortune 500 companies across the globe. We can fabricate enclosures to support a variety of technology and ports, apply finishes to protect the part’s integrity, perform hardware assembly, and add silk screening for easy usage.

delivering precision to the

Entertainment Industry

Pinnacle works with audio-video manufacturers who support professionals working behind the scenes or up on the stage, including fabricating enclosures for high-end lighting rigs, metal meshes for professional audio speakers, frames for speaker line arrays, and outdoor entertainment centers. Each project leverages decades of experience across our technical, production, finish, and quality departments.

delivering precision to the

Renewable Energy Industry

Keeping the power on in extreme locations is the number one job for our customers working in the renewable energy sector, so our top priority is ensuring every rack and enclosure they use is durable, weather-resistant, and secure. The Pinnacle Precision team cuts, forms, and punches large metal sheets to fabricate large cabinets. Our weld, finish, and assembly pros complete the project so that every piece is resistant to the harshest environments and the technology inside continues to work.