A HISTORY OF EXCELLENCE

Forming a strong foundation

Pinnacle Precision boasts a rich history that dates back more than 50 years. We’re proud to work with industry-leading companies that shape our future in medical, communications & technology, renewable energy, aerospace and defense fields. Our core team includes people that have spent 30-plus years here. Each is committed to helping the next generation learn the intricacies of precision manufacturing and assembly. We hold our people in high esteem and strive to create an environment where safety, care, and excellence are our guiding lights.

Established in 1973

The keystone of today’s Pinnacle Precision was placed in 1973 when company founders Don Wright and Ed Randolph opened D&E Precision Sheet Metal. The company provided prototyping, CNC machining, welding, assembly, painting, and silk screen printing services to customers in the audio/visual, medical, and energy sectors.

Today, Pinnacle boasts a wealth of knowledge, experience, and expertise while producing precision metal components used by leading industrial manufacturers. The company’s team continues its focus on delivering high-quality, on-time parts while expanding its capabilities, client base, and training its staff for the next generation.

WE ARE ON A MISSION

We are united to empower our partners to make their aspirations a reality.

Company values

We do the right thing

We never sacrifice our honesty and integrity

We find a way

We find solutions, not excuses

We think forward

We drive action to positively impact our ever-changing world

We are a team

Our strength comes when we work together with mutual respect, support, and collaboration

We own our path

We take responsibility for our actions and hold each other accountable

PINNACLE LEADERSHIP

A team dedicated to customer and team success

The strength of Pinnacle’s leadership team comes from its decades of manufacturing, engineering, operations, and business development experience. Our leaders are committed to driving the business forward with care, accountability, excellence, and positivity and helping the company’s employees learn and grow personally and professionally.

Kevin Beatty

General Manager

Anabel Moreno

Director of Human Resources

Monica Liriano

Director of Quality

Sergio Valdez

Operations

Meet the team

Customer Support

What makes a rock-solid fabrication and solutions shop hum is the people that take the time and care to understand what a customer needs to solve their challenges precisely. Pinnacle’s Customer Service team boasts the experience, expertise, and dedication to ensure our customers get the exact solution they need every time.

Production

Experience and expertise are the first two things customers should look for when picking a sheet metal fabrication shop to produce their parts. After all, anyone can buy equipment. Most of Pinnacle’s production team have worked here for 20 or more years, many for over 30 years. We know what it takes to deliver accurate, on-time parts.

Quality Assurance

Precision, accuracy, and on-time delivery are the things that we stake our reputation on here at Pinnacle. Our Quality Assurance Leads closely monitor the parts and assemblies delivered to customers, keeping us in compliance with ISO:9001, AS9100D, ITAR, and RoHS standards while empowering team members to monitor their stations for technical excellence.

Technical

Pinnacle excels across the board while executing manufacturing, finishing, and quality assurance capabilities, but the Technical team sets up every job for success. Experience, expertise, and diligence are the hallmarks of Pinnacle’s Technical professionals as they uncover production and part efficiencies before manufacturing starts.

The shop

The engine of Pinnacle Precision is a 73,000-square-foot plant that houses a team of 150 dedicated and experienced manufacturing experts leveraging the power of the latest production tools.

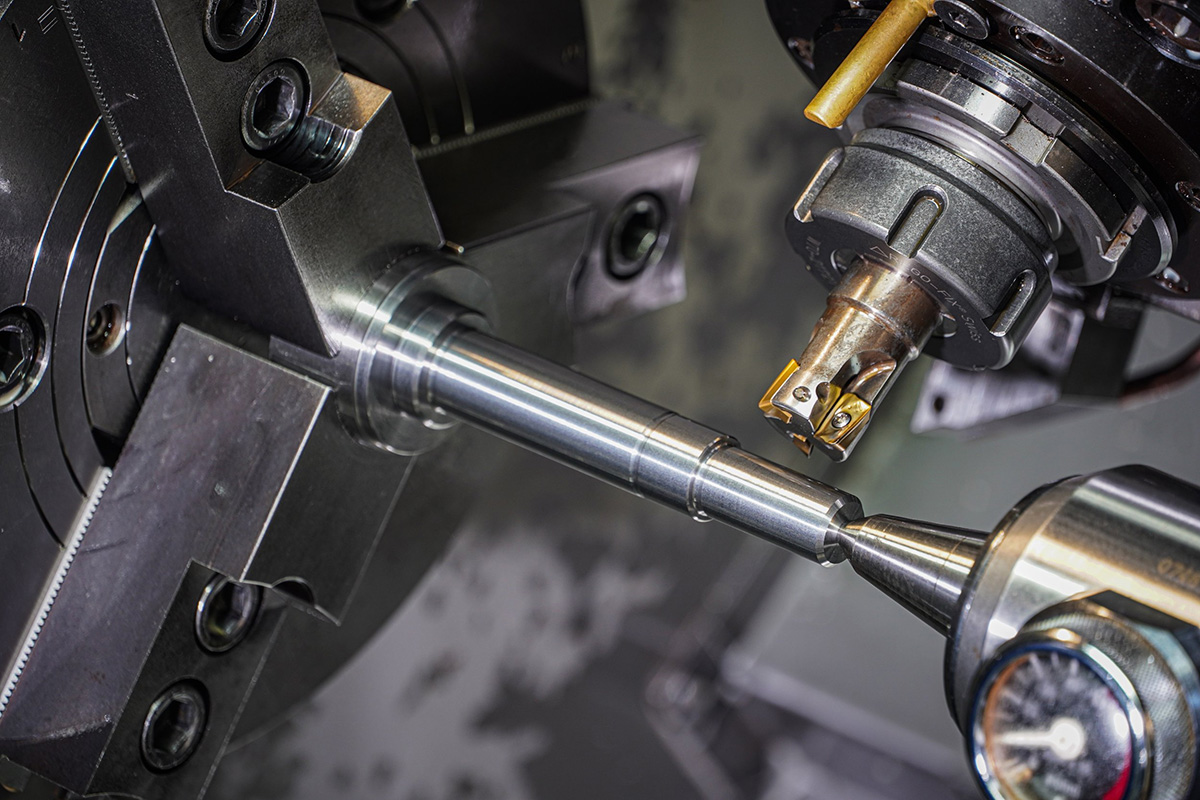

Pinnacle’s production floor includes CNC machining, shearing, punching, forming machines, laser cutting equipment, line grainers, and welding stations. Expert leaders and skilled technicians run each station.

The Painting and Silkscreen departments enhance the durability, useability, and appearance of every part coming off the production floor, making sure our customers can get into production without delay.

A team of support, technical, quality assurance, and management staffers support the plant and constantly seek ways to deliver cost and manufacturing efficiencies to benefit our customers and team.

CNC Machining: Why It’s Critical for Medical-Grade Components

A member of

Pinnacle Precision is a proud member of The Partner Companies group of specialty manufacturers who share a commitment to excellence, precision, and innovation.TPC companies operate as a consortium of capabilities, serving the defense, aerospace, medical, telecommunications, semiconductor, and renewable energy industries.

TPC supports each member entity with expertise in business growth, finance, human resources, and supply chain management. The strength of TPC is the sharing of experience, materials, and resources that its members share.