EXPERTISE & EXPERIENCE

Capabilities

Pinnacle Precision’s reputation as an expert full-service solutions provider with experience in sheet metal fabrication, CNC machining, finishing, total assembly, and quality assurance comes from its 50-plus year history and dedication from meticulous planners and programmers, precise manufacturing crews, and attentive quality assurance professionals.

Our experience extends to fostering and managing a robust supply chain to mitigate risk, enabling us to adhere to tight deadlines and right-in-time delivery schedules.

Each Pinnacle team member dedicates their workdays to delivering on the promise of a new level of precision with the spirit of partnership, teamwork, responsibility, and forward-thinking.

Our 73,000-square-foot facility in Southern California is ISO 9001 and AS9100 certified, surpassing industry standards for quality, precision, and accuracy. We use modern technology and decades of experience to manufacture parts that matter.

We invite you to learn more about our core capabilities:

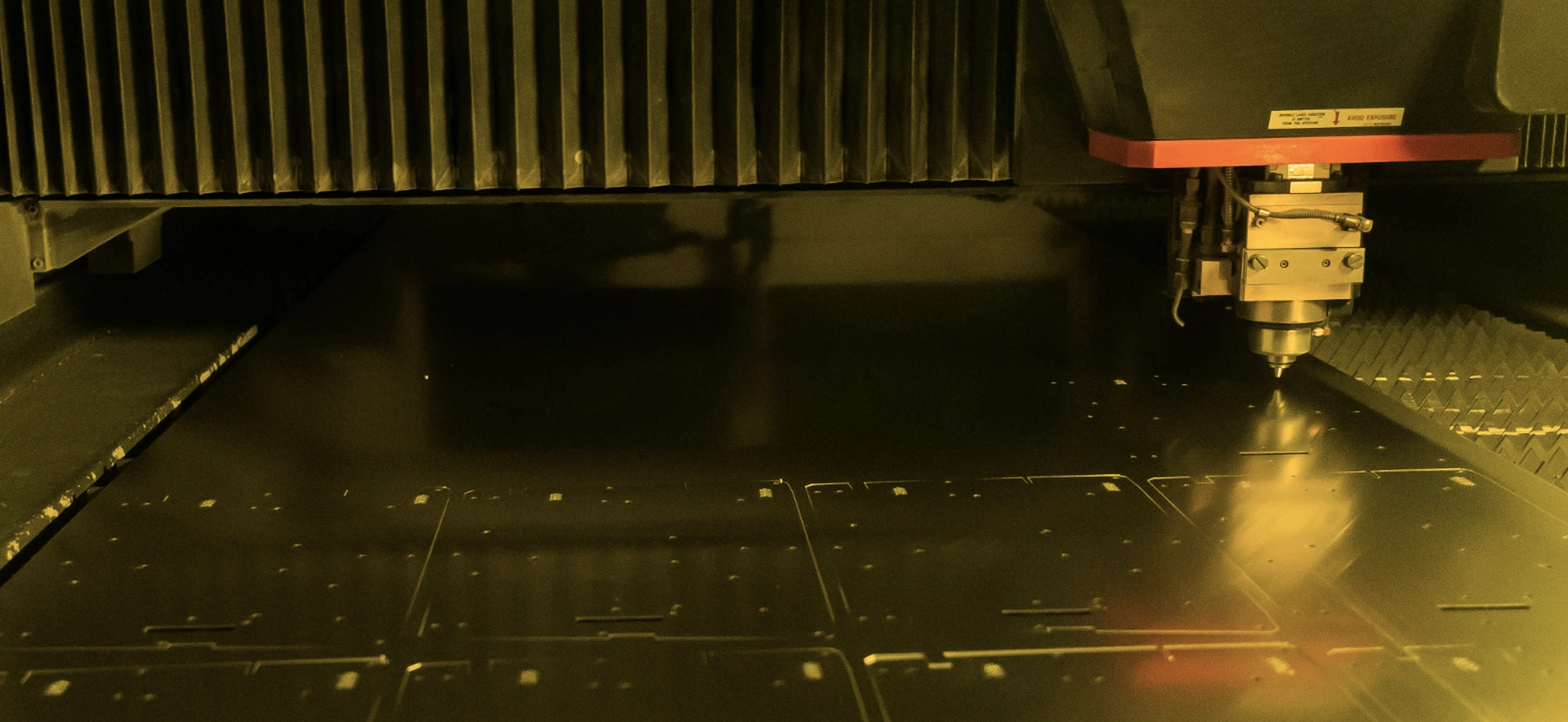

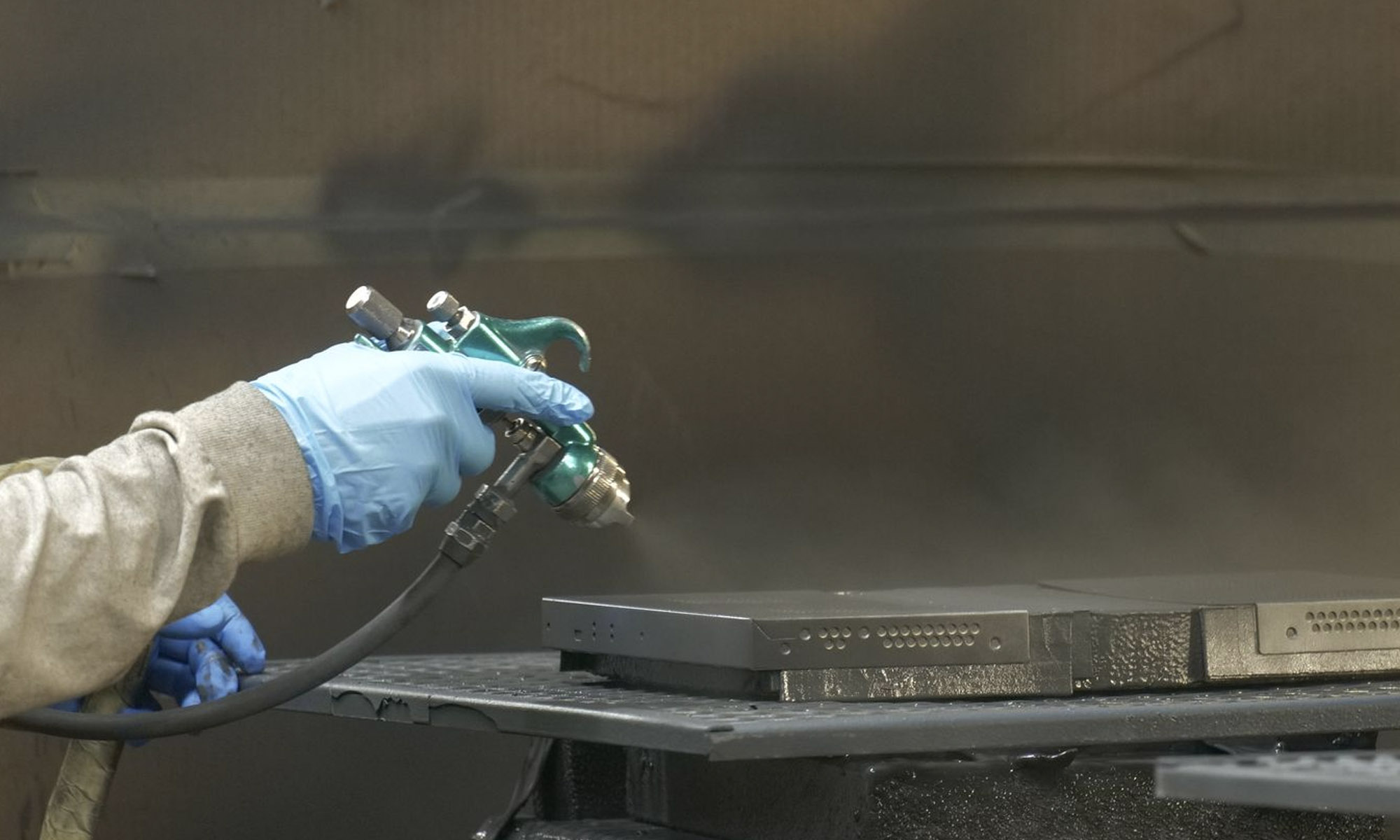

Precision Sheet Metal Fabrication

Perfect parts, components, and assemblies start with the highest attention and precision while cutting, punching, forming, welding, and grinding raw metal materials. Our teams leverage CNC-powered machines to fabricate accurate, reliable, and long-lasting metal parts.

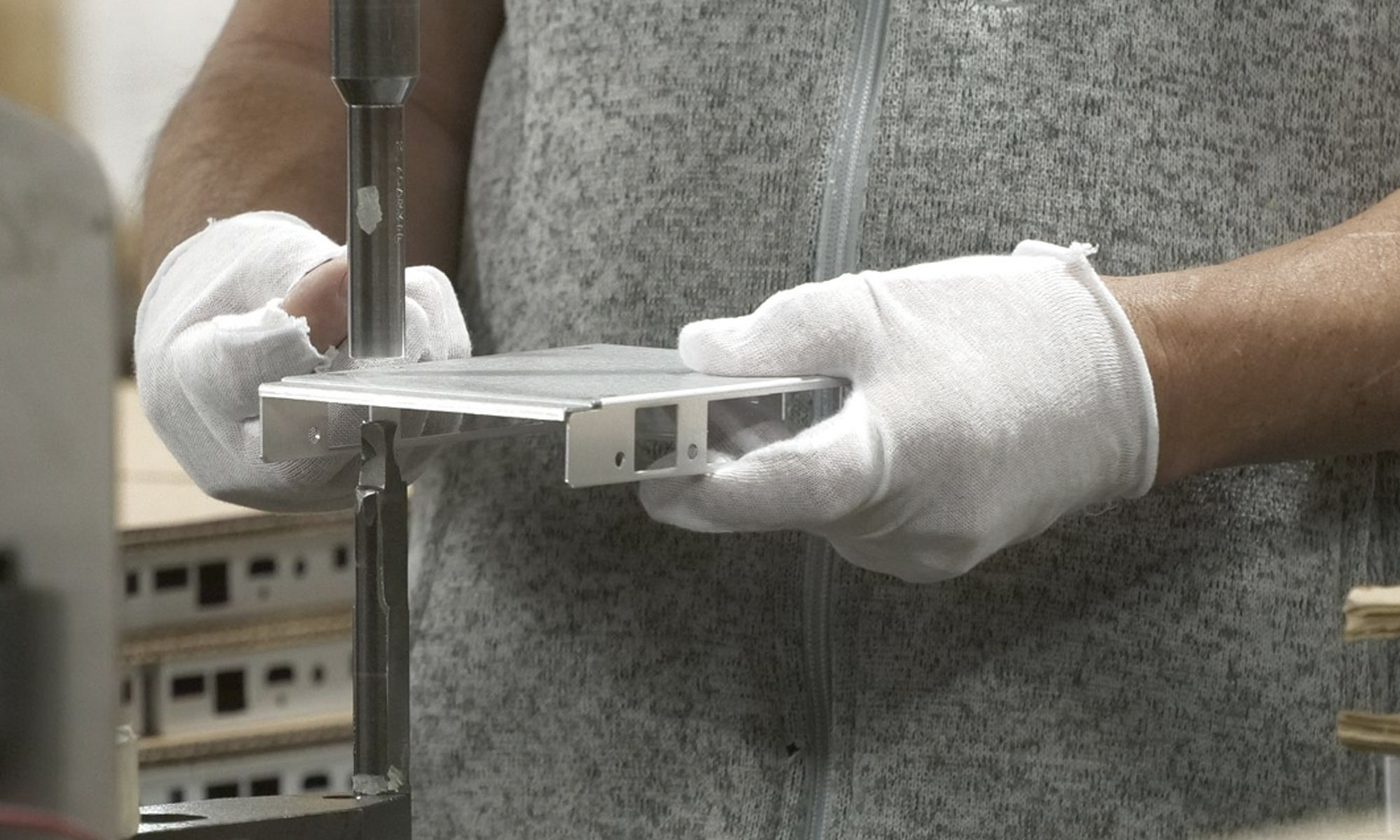

Precision CNC Machining

Pinnacle’s collection of multi-axis CNC machines, expert programmers, and master operators produce machined components with intricate geometries to the tightest tolerances. Our machine shop delivers dependable and accurate products for prototype, high mix/low volume, and high volume production.

Total Assembly

We look for ways to collaborate with our customers on every project, delivering value-add services to enhance every part and component with produce. Our expert assembly team installs hardware, components, harnesses, electronics, sealants, and anything else our customers require, matching material tolerances with component alignments to ensure every piece performs as expected.

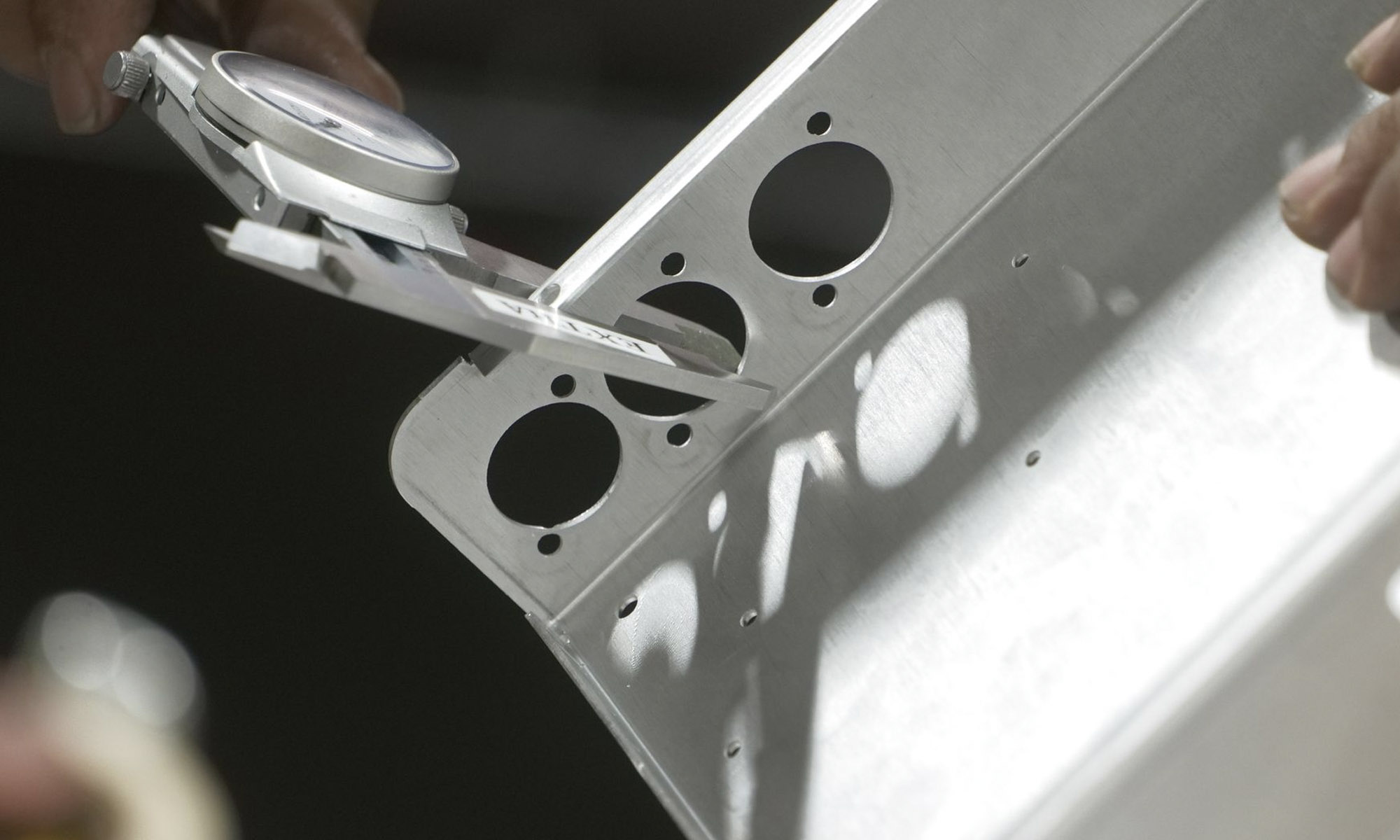

Quality Assurance

Pinnacle’s operators and quality assurance personnel aim to exceed the most stringent inspection standards for every part, component, and assembly produced at our plant. Every operator at our facility is empowered to inspect our daily output as our QA team maintains the procedures to maintain ITAR, ISO9001:2015, AS9100D, and RoHS certifications.