EXPERTISE & EXPERIENCE

Capabilities

Pinnacle’s reputation for precise, durable, and strong metal fabrication solutions comes from its 50-plus years of experience, expert manufacturing crews, meticulous planners and programmers, and quality assurance professionals.

Our experience extends to fostering and managing a robust supply chain to mitigate risk, enabling us to adhere to tight deadlines and right-in-time delivery schedules.

Each Pinnacle team member dedicates their workdays to delivering on the promise of a new level of precision. We are a total assembly partner, seamlessly integrating parts, components, wire harnesses, and other hardware into complete electro-mechanical solutions.

Our 73,000-square-foot facility in Southern California is ISO 9001 and AS9100 certified and surpasses industry standards for quality, precision, and accuracy. We use modern technology and decades of experience to manufacture parts that matter.

We invite you to learn more about our Capabilities:

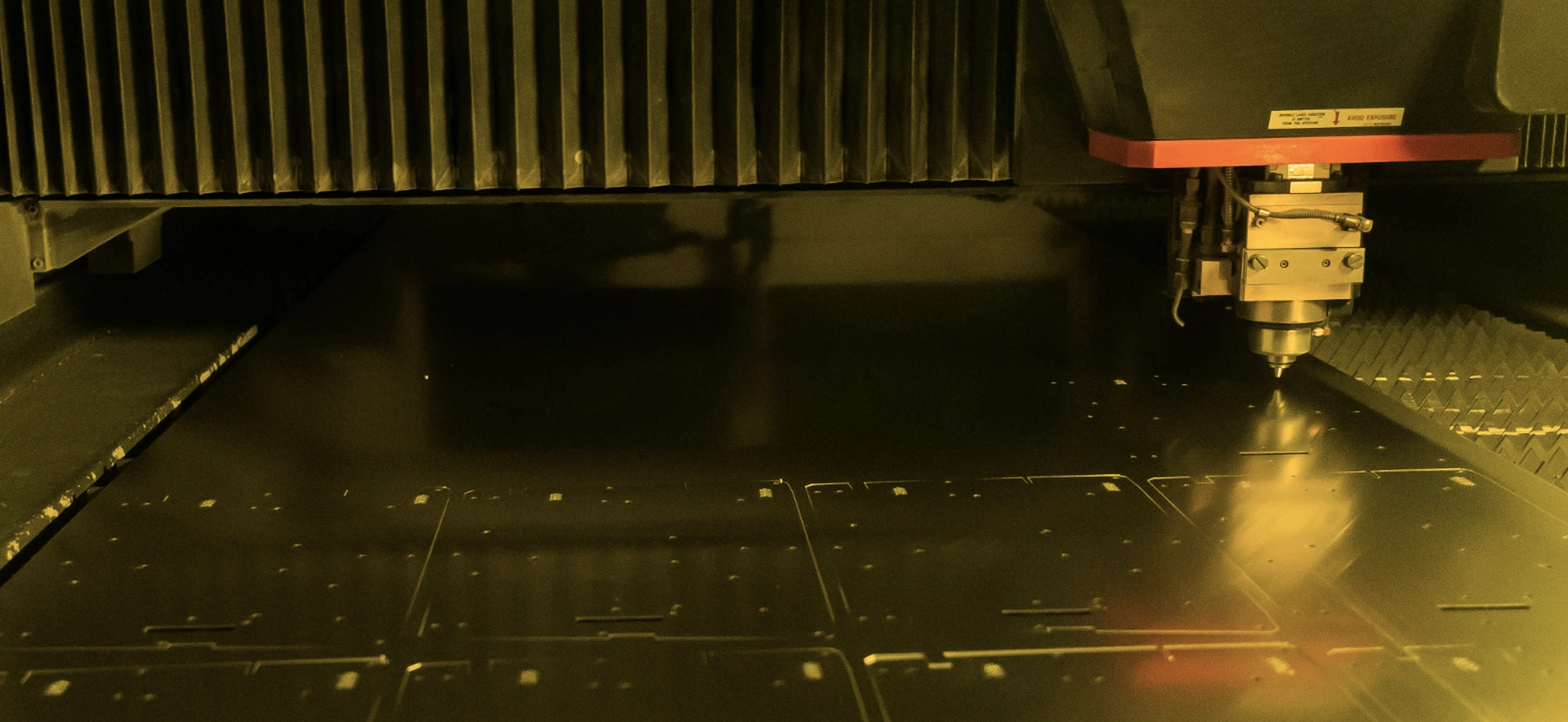

Cutting

Perfect parts start with precise cuts and shears from one of the CNC laser machines on our production floor.

Punching

CNC punching machines and presses turn raw materials into precise parts efficiently and accurately.

Forming

CNC forming presses deliver accurate and durable parts up to 10 feet in length from a large selection of dies and tools.

Machining

Multi-axis CNC machines and expert programmers enable precise manufacturing to the tightest tolerances and intricate designs.

Welding

Spot, tack, TIG, and MIG experts work with a range of materials and gauges for fast and accurate welds.

Grinding

Wet and dry line graining, deburring, grinding, and sanding remove any imperfections created during manufacturing to prep parts for finishing.

Finishing

Expert finishing makes a part functional while making it resistant to environmental factors and corrosion and adding cosmetic features.

Assembly

Functional, ready-to-use parts are assembled on our production floor to speed up customer implementation.

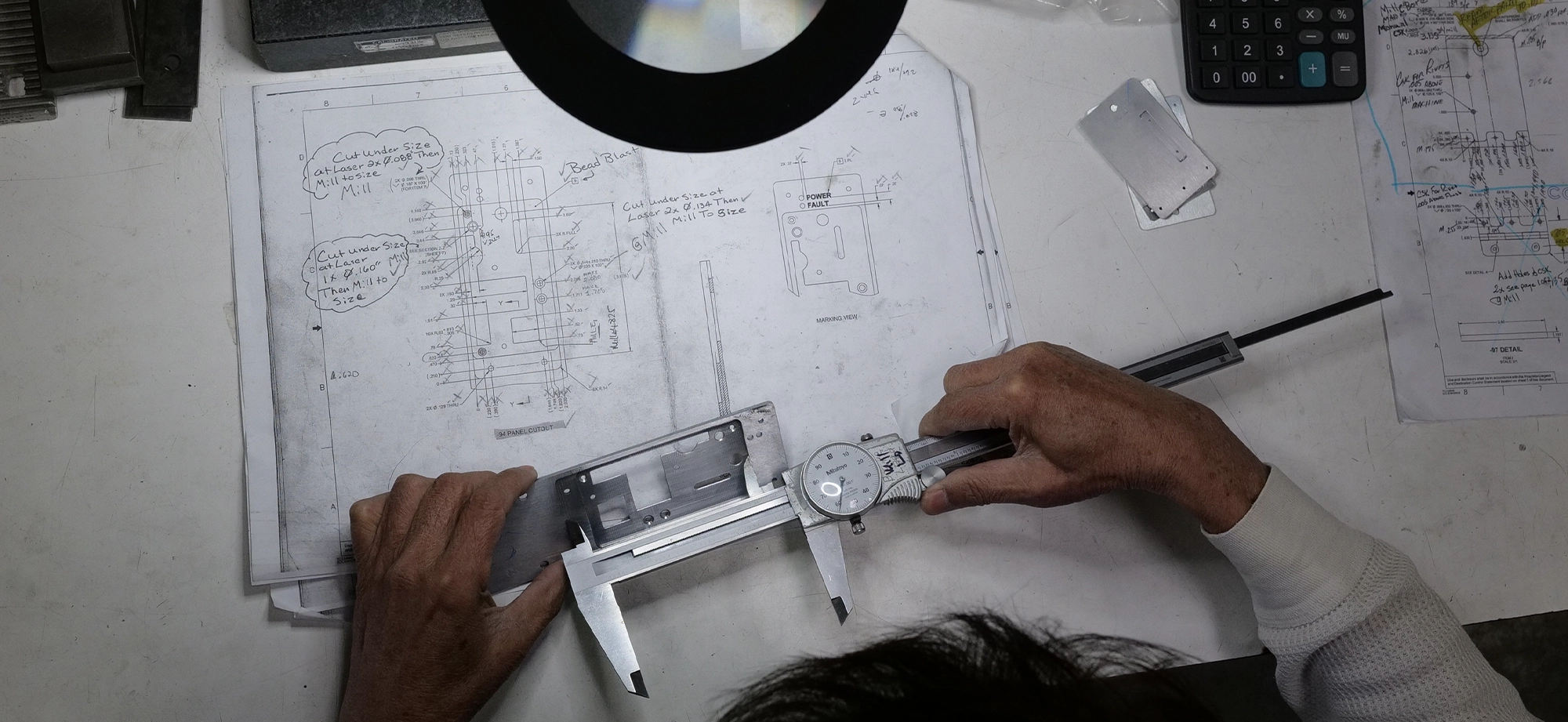

Quality Assurance

Computer-aided quality control and laser inspection ensure that parts manufactured at Pinnacle are accurate and durable.