We are experts in

Total Assembly Solutions

When you require top-tier quality and functionality in metal products, you need a trusted assembly team renowned for delivering precision. We are experts in full-service Total Assembly with a comprehensive process that meticulously joins and integrates metal parts, machined components, and wire harnesses into accurate, functional, and seamless electro-mechanical assemblies.

Our team considers every aspect of the final product, considering everything connected or attached to it to meet the highest functional standards. We match material tolerances and component alignments to ensure that every piece fits together flawlessly and performs its intended function with utmost efficiency and durability.

Let’s talk about your most demanding requirements.

The tools we use for

Expert assembly

-

(9) Semi-Automatic Presses for threaded fastener installations

-

(6) Auto-Presses with auto feeds

-

(2) Hardware Presses with auto feeds

Assembly Process

Our proven total assembly process

Our expert team of assemblers uses various techniques to achieve flawless functionality, structural integrity, and dimensional accuracy while meeting stringent quality standards.

Our proven process includes the following:

Component Fabrication: We fabricate each metal component using a variety of techniques, including cutting, bending, punching, milling, turning, and welding.

Quality Control: We carefully inspect each component to ensure it meets exacting quality standards and specifications.

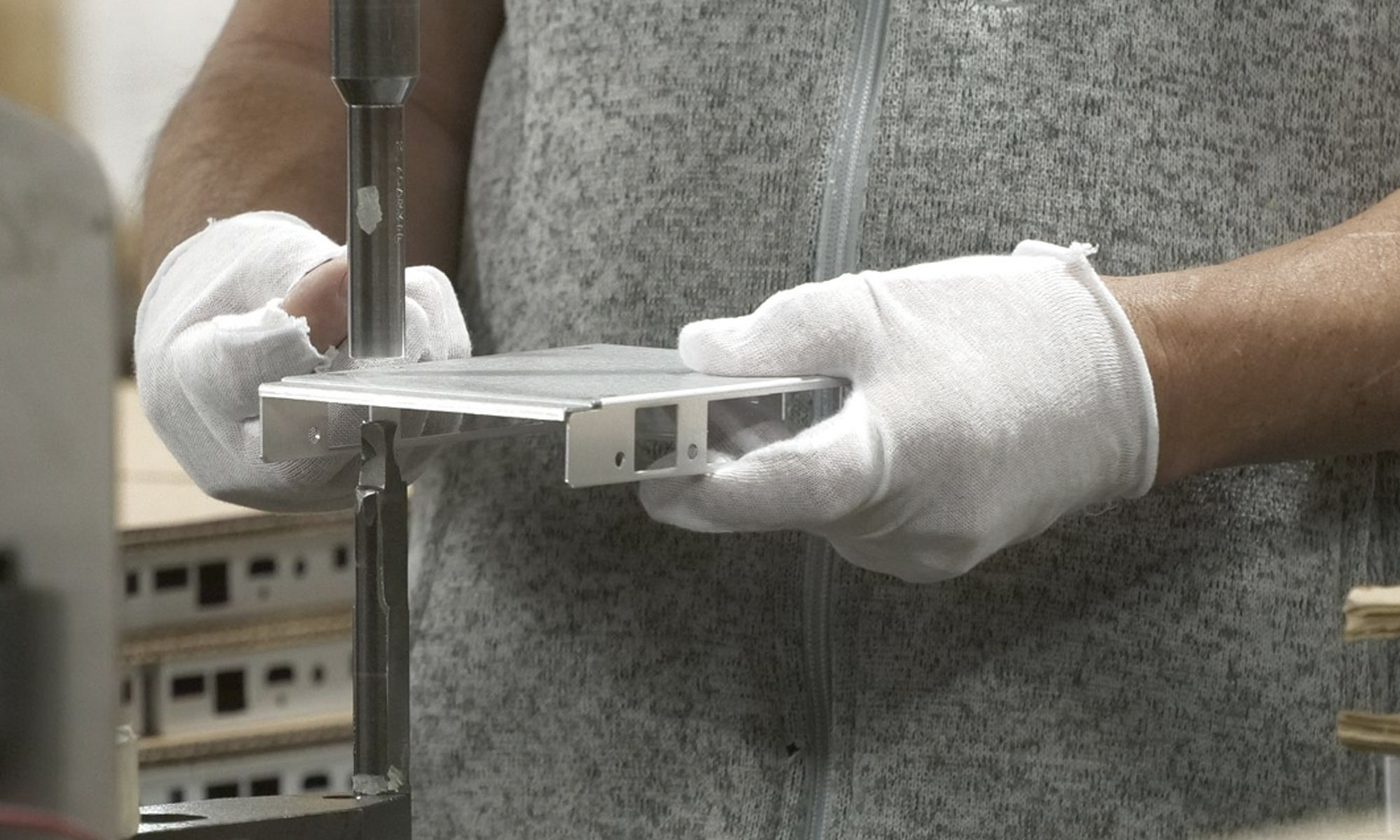

Electro-Mechanical Assembly: The individual components are then assembled using welding, fasteners, adhesives, or other suitable methods. The assembly process requires precise alignment and fit to ensure the final product’s structural integrity and functionality.

Finishing: To enhance appearance and protect the product against corrosion, finishing touches such as painting, coating, or polishing may be applied after assembly.

Quality Assurance: The finished product undergoes rigorous quality assurance checks to ensure it meets all safety and design specifications.

how we deliver

The Pinnacle process

Customers from leading medical, aerospace, information and communications technology, energy, and entertainment companies come to Pinnacle Precision because they’ve experienced a new level of precision.

Our teams boast decades of experience, working with product sizes ranging from inches to yards and a broad range of sheet metal alloys and finishes.

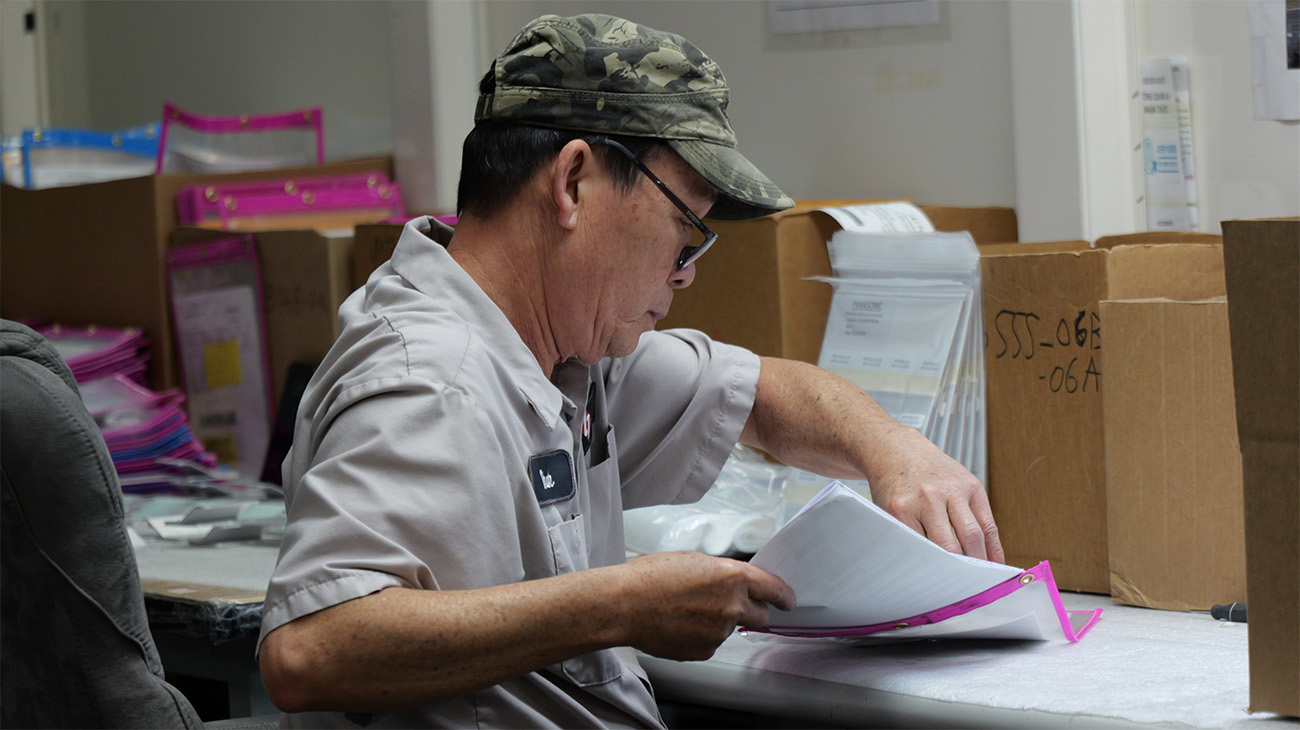

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our manufacturing experts utilize CNC laser cutting and punch presses for precise sheets that are then delivered to our machining, forming, welding, and finishing departments. From there, we help our customers with assembly, hardware installation, and seal applications before Pinnacle’s quality assurance team carefully looks at the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

a question we get:

What total assembly services does Pinnacle offer?

The Pinnacle Precision Assembly team works closely with our Customer Service, Technical, and Quality Assurance departments to ensure that the parts coming out of our Anaheim facility to help our customers keep their production floors running smoothly.

Our crew of Assemblers installs hardware, seals, and wiring as requested by our customers. Each is highly trained and experienced in working with parts for the energy, aerospace, and medical industries.

THE INDUSTRIES WE SERVE

Who relies on us for assembly services?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.

Full Service Part Assembly & Fabrication

Why work with a total assembly metal manufacturer?

When you work with a total assembly metal manufacturer, you get peace of mind knowing that your components will flawlessly align while adhering to strict tolerances and quality standards.

Delivering the perfect fit and functionality of your metal components, this turn-key solution streamlines the entire production process, reducing lead times and costs by consolidating various fabrication steps under one roof. It’s also:

More Efficient – By streamlining the manufacturing process, you can avoid the complexity of managing multiple suppliers for individual components, saving valuable time and resources.

More Economical – While it might seem counterintuitive, total assembly can often lead to cost savings in the long run. You can avoid potential coordination issues, rework costs, and delays associated with managing multiple suppliers by having one company handle the entire assembly process.

More Timely – Streamlining the assembly process can lead to shorter lead times for project completion, allowing you to meet project deadlines effectively.

Customizable – Total assembly allows for greater customization and flexibility in design. With close collaboration with clients, manufacturers can ensure that the final product meets specific requirements and can even accommodate last-minute design changes.