We are experts in

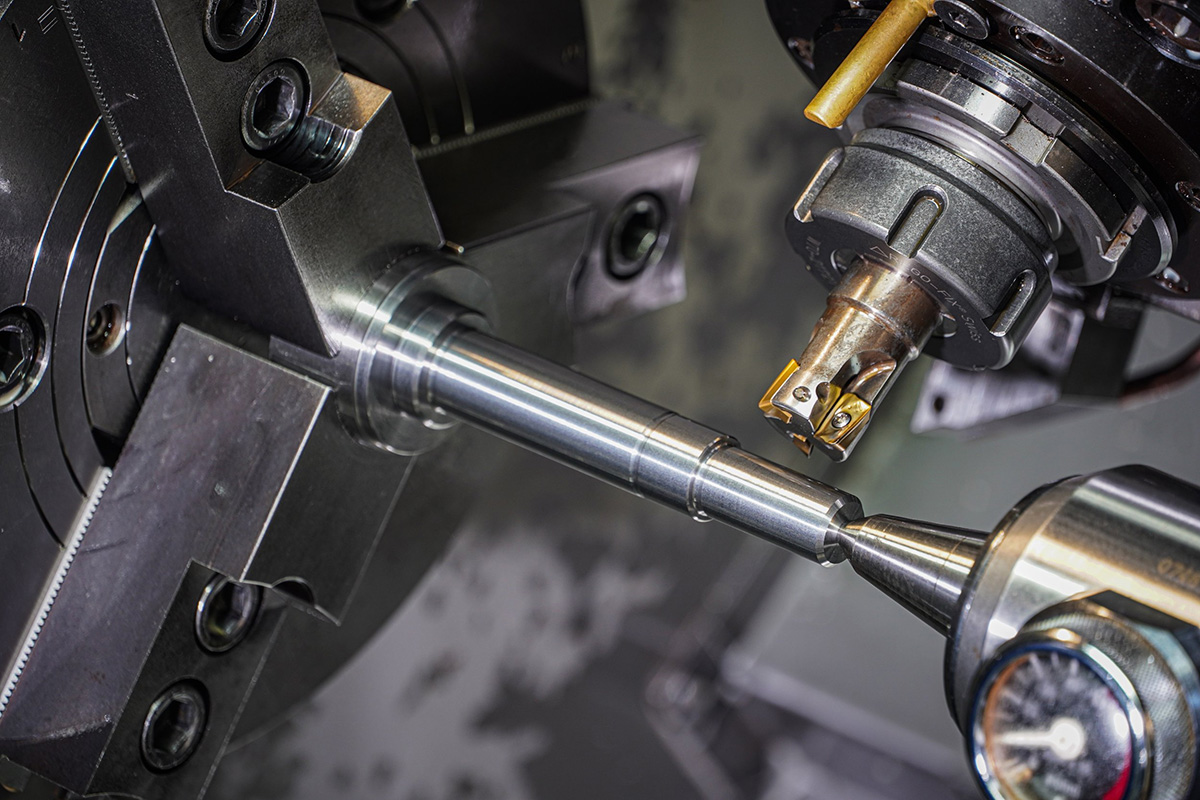

CNC Turning

Pinnacle Precision’s advanced 73,000-square-foot manufacturing facility features several CNC machining centers, including new CNC turning and milling machines.

Pinnacle’s philosophy of supporting our customers with new technologies and capabilities continues as we implement new CNC machines, including a new CNC lathe machine that offers Y-axis live tooling and sub-spindle features. These features allow our operators to manufacture more complex parts with fewer production delays.

Our specialized team of professionals has experience working with a wide range of metals, including aluminum, stainless steel, and titanium, as well as plastic parts and composite applications.

With a proven track record across various industries, Pinnacle Precision has taken steps to ensure we continue providing our customers with top-tier service and quality through investments in technology and the latest equipment.

The tools we use for

Delivering Precision CNC Turning Services

Our additional investment in a new multi-axis CNC lathe enables us to further expand on the part production of complex designs with unparalleled accuracy and efficiency. Also, adding this equipment increases manufacturing possibilities while reducing set-up times and operator involvement that was previously required.

Pinnacle’s new equipment bolsters our ability for rapid turnaround via these features:

Live Tooling Lathe

-

Two machines and two set-ups would now be one machine and one operator. More features mean less downtime between operations while still maintaining tight tolerances.

-

A “live” cutting tool means that instead of rotating the workpiece, we can add different features, such as tapped and counterbored holes.

Sub-Spindle

-

We now have increased versatility by being able to cut multiple faces without having to reposition the workpiece. This leads to more consistently turned parts and reduced visible tool marks based on minimal intervention through the manufacturing process.

-

Standard CNC turning machines typically require multiple set-ups to complete a job. The sub-spindle allows less set-up time/frequency and reduces the chance of error during those set-ups.

Capacity and Speed of Cutting Tool

-

12 Station Turret (24 positions) and 0.11 seconds indexing time

-

6,000 rpm main and sub-spindle speeds

-

6,000 rpm main and sub-spindle speeds

Technology Advantages for CNC Turning

-

Taper Turning

-

Circular Interpolation

-

CNC tailstock for up to 50% reduction in setting time

The additional CNC lathe equipment allows Pinnacle’s Technical and Production crews to turn a wide variety of parts and components to the tight, repeatable tolerances expected of the industry and our clients.

Our process starts with detailed CAD files, which direct the programming of our CNC machines, ensuring that every part and component meets or exceeds our customers’ stringent requirements.

how we deliver

The Pinnacle of CNC Turning Service

The addition of new CNC turning machines further expands our ability to ensure the highest standards of precision and quality are maintained from start to finish.

The precision CNC turning process we use includes several key components:

Customer Support: Our dedicated team translates customer needs into detailed action plans. All we need is a technical drawing/desired geometry.

Technical Planning: Our technical team of CNC machine experts develops optimized turning strategies.

Machining Process: We machine high-precision parts with our advanced CNC turning equipment, ensuring minimal waste and maximum efficiency by using high-quality cutting tools in tandem with the latest technology.

Quality Assurance: Every component undergoes rigorous inspection to guarantee it meets client specifications, ensuring high precision tolerances are held with every turn.

Finishing Options: After the turning process, parts are finished to meet the required surface specifications. We also offer additional finishing services, like corrosion-resistant anodizing and plating and aesthetically pleasing powdered paint or powder coating.

a question we get:

Why choose Pinnacle Precision for CNC Turning Services?

From prototypes to volume production, our dedicated team of professionals has the CNC lathes necessary to bring your designs to fruition.

Our rapid prototyping work is critical in keeping projects on schedule, enabling our clients to meet their essential deadlines. Our teams and advancements in equipment and technology help us meet client deadlines with minimal delays.

On-time delivery is the foundation of our CNC lathe services and the entire machine shop. Our team understands the importance of providing accurate CNC machined parts and components in a timely manner.

Here at Pinnacle Precision, we’re adamant about maintaining the highest standards in precision machining, ensuring every part meets exact specifications. Our team of engineers and operators brings years of experience and expertise to every project, while our customer-centric approach ensures we deliver solutions tailored to the unique needs of each client. Simply put, if we aren’t satisfied with the quality, we don’t send it out the door.

Our continued investment in multi-axis CNC machining processes enables us to accurately produce complex metal parts, making us a trusted partner for high-quality, high-volume CNC machining for clients across a range of leading industries.

THE INDUSTRIES WE SERVE

Who relies on Pinnacle Precision for CNC turning services?

Pinnacle Precision manufactures parts and components used across the global marketplace of advanced manufacturers in vital industries, including medical, aerospace, defense, energy, entertainment, and information & communications. Our machine shop is dedicated to ensuring that we provide quality parts and components to our customers each and every time.

Whether your company is small or large, the diversity of our CNC turning services enables us to be flexible and adapt to your needs without incurring enormous set-up and operator costs typically associated with outdated, less advanced CNC machines.