We are experts in

Quality Assurance

Pinnacle aims to exceed industry standards and customer expectations while delivering essential parts at just the right time. The Quality Assurance motto is “quality people make quality parts,” so the team empowers every employee to act as a Quality Control expert in their department and performs regular training sessions. Pinnacle’s Quality Assurance team establishes and maintains our procedures to comply with ITAR, ISO9001:2015, AS9100D, and RoHS certifications.

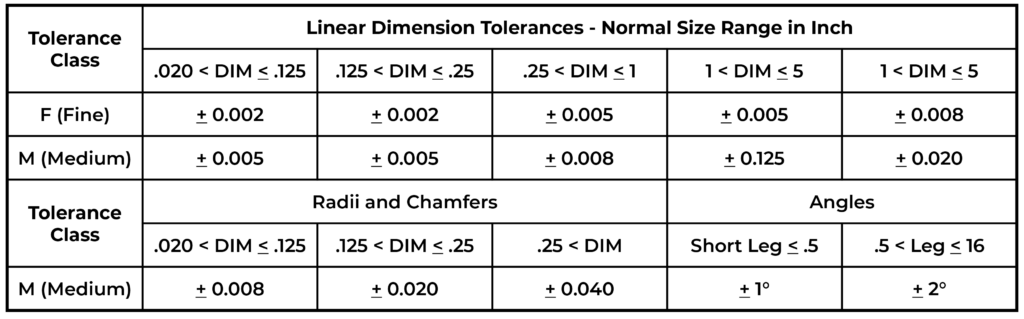

General Dimensional Tolerances

Dimension Range

DIM ≤ 8″ [203mm]

8″ [203mm] < DIM ≤ 16″[406mm]

16″[406mm] < DIM ≤ 36″[914mm]

Edge to Edge, Hole to Hole, Edge to Hole on Flat

± 0.005″ [0.13mm]

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

Edge to Hole to Bend

± 0.010″ [0.25mm]

± 0.015″ [0.38mm]

± 0.020″ [0.38mm]

Bend to Bend

± 0.020″ [0.51mm]

± 0.020″ [0.51mm]

± 0.030″ [0.76mm]

Angular Tolerance

±2°

The tools we use to

Ensure excellence

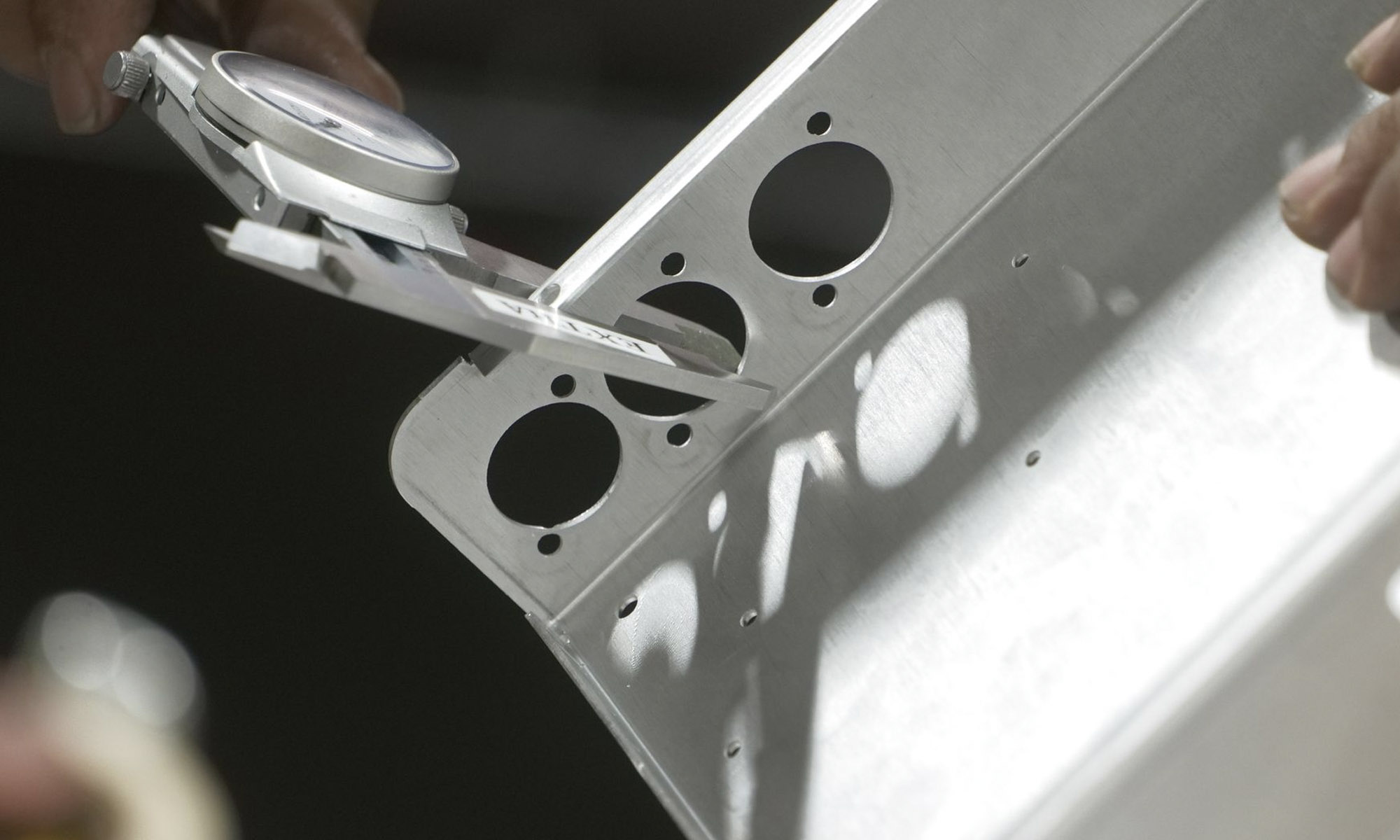

Fabricating and finishing are the first steps in delivering accurate assemblies, parts, and components. Our Quality Assurance team reviews customer requirements, monitors the manufacturing processes, and inspects projects for accuracy and durability using laser, digital, and dial tools.

THE MATERIALS WE USE

General Machining Tolerances

how we deliver

The Pinnacle process

Customers from leading medical, aerospace, information and communications technology, energy, and entertainment companies come to Pinnacle Precision because they’ve experienced a new level of precision.

Our teams boast decades of experience, working with product sizes ranging from inches to yards and a broad range of sheet metal alloys and finishes.

Each project that comes into Pinnacle’s Southern California headquarters receives the highest level of attention. Our Customer Support team excels in translating customer needs into actionable plans for our Technical, Production, and Quality Assurance teams.

Our manufacturing experts utilize CNC laser cutting and punch presses for precise sheets that are then delivered to our machining, forming, welding, and finishing departments. From there, we help our customers with assembly, hardware installation, and seal applications before Pinnacle’s quality assurance team carefully looks at the final product.

The difference between Pinnacle and any other company is our team-forward integrated approach and solutions-first mentality. We look forward to proving our promise to you.

a question we get:

How does Pinnacle measure accuracy?

The Quality Assurance team at Pinnacle Precision actively inspects the manufacturing process when a project hits the facility’s production floor. We partner with the Technical and Production crews, empowering them to check parts as they move through the fabricating steps.

One thing that sets Pinnacle apart from other metal fabrication companies is the level of expertise on our production floor. Many of our team members have decades of fabrication experience and understand the importance of accuracy and precision.

To enhance experience and expertise, Pinnacle uses calipers, micrometers, and several types of gauges — pin, GO/NO GO, height, depth, radius, and surface roughness. We also use paint chips to match paint colors to customer requirements.

The company also boasts a laser rapid inspection system that measures the finest detail, dimension, and tolerance. That level of attention is essential when delivering Class A parts used in life-saving applications.

THE INDUSTRIES WE SERVE

Who relies on Pinnacle Precision?

Pinnacle Precision manufactures parts used across the world’s most advanced and vital industries, including medical, aerospace, information & communications, energy, and entertainment. Our advanced approach to every capability means that parts created here can withstand the harshest environments and look good year after year.