When it comes to modern manufacturing, precision sheet metal parts are driving innovation and efficiency across the world’s leading industries. Delivering versatility, durability, and cost-effectiveness, these powerful parts are helping to advance technologies in key sectors, including aerospace, medical, and electronics – just to name a few.

The precision of these parts is critical for producing high-performance systems and devices, especially for applications where failure is not an option.

With a focus on precision and strength, Pinnacle Precision has earned a rock-solid reputation for custom sheet metal parts and components that offer performance, reliability, and durability in even the harshest environments. Leveraging advanced sheet metal fabrication techniques, decades of experience, and a commitment to excellence, our expert team consistently delivers superior precision sheet metal components, parts and assemblies tailored to meet exacting standards.

In this article, we explore the significance of precision sheet metal parts, their key applications, and the wide range of advantages they provide.

What Are Precision Sheet Metal Parts?

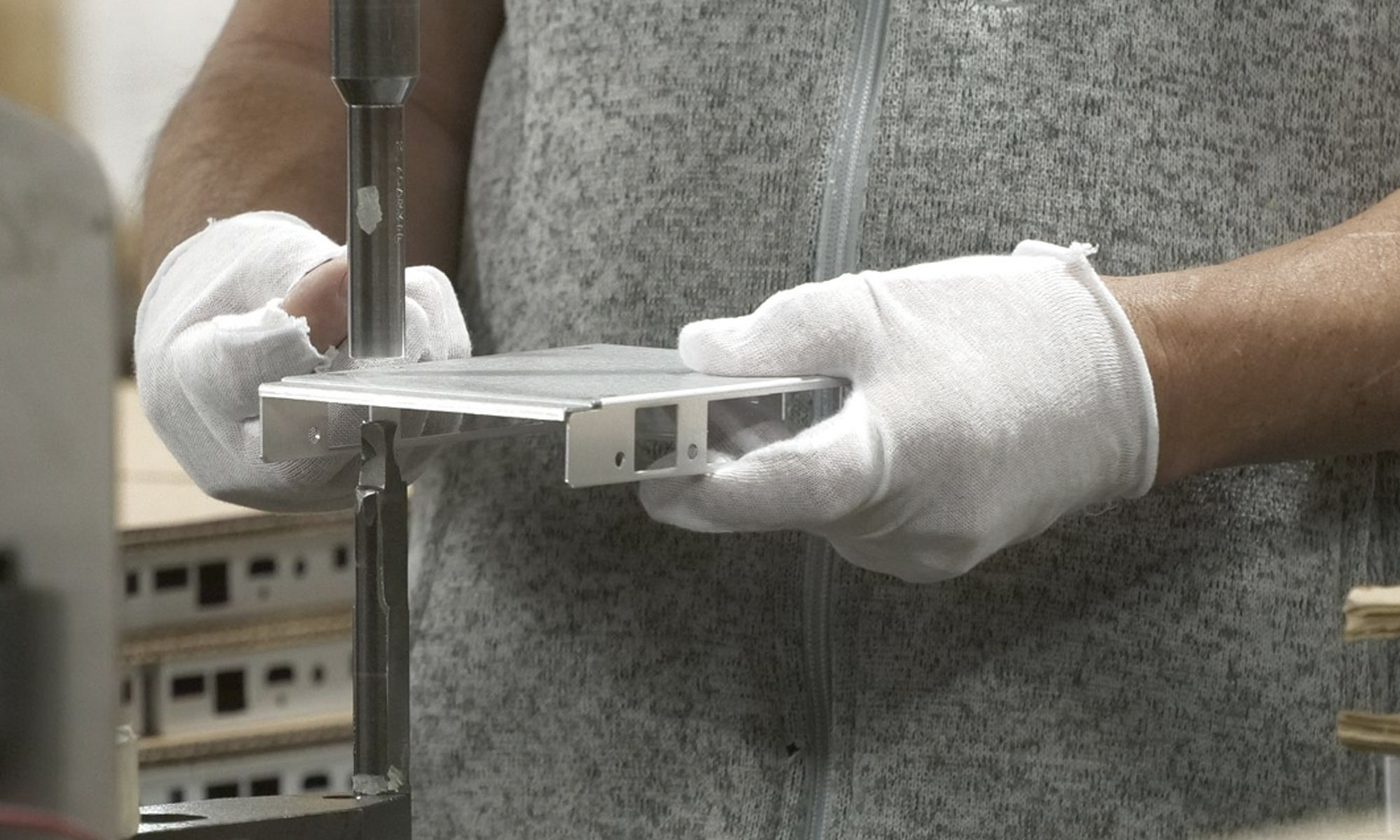

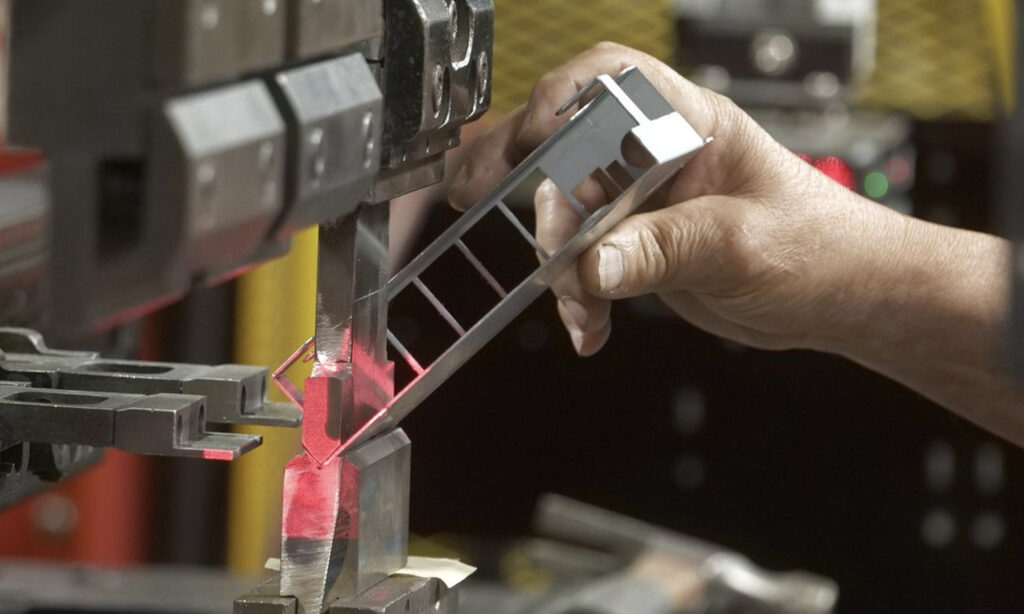

Precision sheet metal parts are components fabricated from thin metal sheets through a series of processes, including cutting, bending, punching, and assembly. These parts are meticulously engineered to meet exact specifications, ensuring quality, accuracy, and reliability.

At the heart of precision sheet metal fabrication is the use of advanced machinery such as CNC laser cutters, sheet metal punch, press brakes, and welding equipment. This technology, together with innovative fabrication processes, enables manufacturers to produce parts with tight tolerances and intricate designs, ensuring they meet the stringent standards of highly regulated industries like aerospace and medical.

The key characteristics of precision sheet metal parts include:

- High Accuracy: Every component is crafted to exact dimensions to ensure compatibility and performance.

- Reliability: These parts withstand demanding conditions, making them ideal for critical applications.

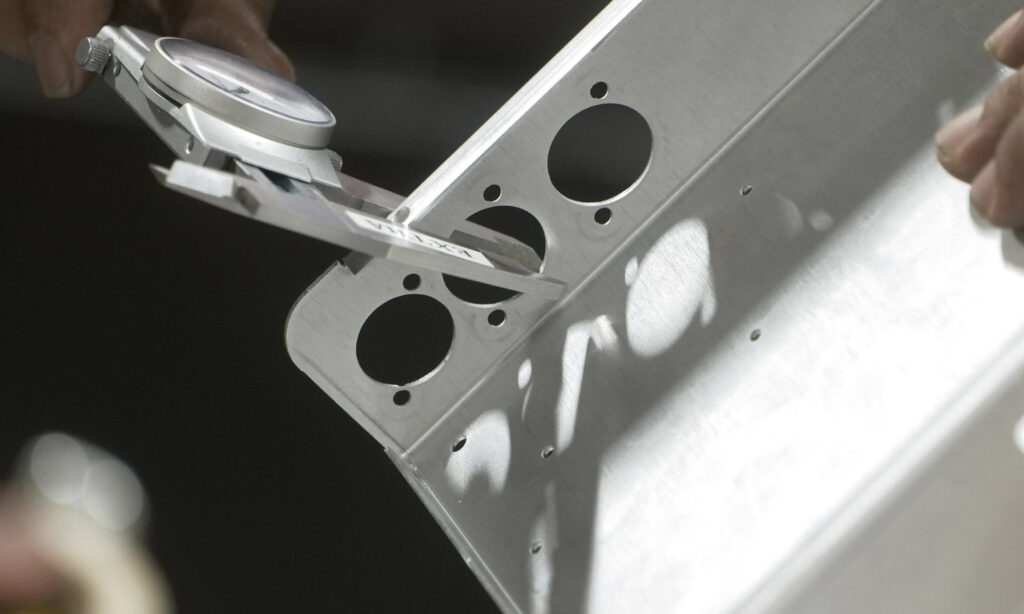

Quality Assurance: Rigorous testing and quality control processes guarantee consistent excellence.

The Importance of Precision in Sheet Metal Fabrication

In today’s modern industries, even the slightest deviation can have significant consequences. That’s why achieving high precision in sheet metal fabrication is critical, ensuring that components fit, function, and perform as intended.

At Pinnacle Precision, we take an integrated approach to our work. By combining technical expertise, advanced technology, and a solutions-first mentality, we deliver unparalleled precision and reliability. Our commitment to quality and innovation has made us a trusted partner for industry leaders across the medical, aerospace, defense, communications, and renewable energy sectors.

Applications of Precision Sheet Metal Parts Across Industries

A variety of industries depend on precision sheet metal fabrication for high-quality, performance-driven components.

Key sectors include:

Aerospace

Precision sheet metal parts are essential for creating lightweight, durable components used in aircraft and spacecraft. From structural supports to intricate assemblies, these parts must meet strict quality and safety standards to ensure reliability in challenging environments.

Medical

In the medical field, precision is paramount. Sheet metal parts are used in surgical devices, diagnostic equipment, and implantable devices, where accuracy and biocompatibility are critical. These components must also adhere to strict regulatory standards to ensure patient safety.

Electronics

The electronics industry relies on precision sheet metal parts for casings, brackets, and intricate components used in circuit boards and devices. These parts help protect sensitive electronics from environmental factors and electromagnetic interference, ensuring optimal performance.

Automotive

From chassis components to custom brackets, precision sheet metal parts play a significant role in automotive manufacturing. Their durability and ability to be customized make them ideal for high-performance and luxury vehicles.

Pinnacle leverages the power and accuracy of CNC-powered machines across our 73,000-square-foot production floor while answering the call from industry-leading medical, aerospace, defense, communications, technology & information, entertainment, and renewable energy companies.

Advantages of Precision Sheet Metal Parts

Delivering numerous advantages over traditionally machined parts, precision sheet metal parts have become the preferred choice for some of the world’s leading industries.

The main advantages of precision machined parts include:

Versatility

Precision sheet metal can be fabricated into an extensive range of shapes and designs, making them perfect for various applications and requirements.

Cost-Effectiveness

Advanced manufacturing processes minimize waste and reduce production costs, making precision sheet metal parts an economical solution for both small and large-scale projects.

Durability and Strength

These components are designed to withstand harsh environments and demanding conditions, ensuring long-term performance.

Customization

Precision sheet metal parts can be tailored to meet specific design and functional requirements, allowing manufacturers to achieve unique solutions for complex challenges.

Improved Efficiency

With their high accuracy and compatibility, precision sheet metal parts contribute to smoother assembly processes and enhanced overall efficiency.

The team at Pinnacle are experts in precision sheet metal fabrication. Our expert team utilizes the latest CNC technology and decades of experience to support our customers with sheet metal fabrication, machining, finishing, total assembly, and quality assurance expertise.

The Critical Role of Material Selection in Precision Metal Fabrication

Material selection is a pivotal aspect of precision sheet metal manufacturing, with the choice of materials directly impacting the performance, weight, durability, and corrosion resistance of the final product.

Common materials include:

- Steel: Renowned for its strength and durability, steel (both stainless and cold-rolled steel) is ideal for applications requiring high structural integrity.

- Aluminum: Lightweight and corrosion-resistant, aluminum is a popular choice for aerospace and electronics industries.

- Copper: Known for its excellent conductivity, copper is often used in electrical applications.

Selecting the right material ensures that components meet the specific needs of their intended applications, optimizing performance and longevity.

The trusted team at Pinnacle are masters of material selection. Our crews work with product sizes ranging from inches to yards, a broad range of sheet metal alloys and finishes, and run from prototype to production.

Pinnacle Precision’s Expertise in Precision Sheet Metal Fabrication

Pinnacle Precision is a trusted name in precision sheet metal manufacturing, producing parts for some of the world’s most advanced industries.

We set the standard in precision CNC machining, finishing, and total assembly, offering end-to-end solutions for the most demanding industries. With advanced capabilities such as fiber laser cutting and computer numerical control (CNC) technology, we deliver unparalleled accuracy and efficiency for even the most intricate designs. Our in-house powder coating services ensure a durable, high-quality finish, providing a complete manufacturing solution tailored to your exact specifications.

Our commitment to excellence is evident in every aspect of our operations.

- State-of-the-Art Facilities: Our 73,000-square-foot production floor houses CNC-powered laser cutting machines, dozens of press brakes (50- to 125-ton capability), and dedicated welding and grinding spaces.

- Unmatched Expertise: Our Technical, Production, and Quality Assurance teams bring decades of experience to every project, ensuring superior results.

- Customized Solutions: We work with a broad range of sheet metal alloys and finishes, delivering tailored solutions for runs ranging from prototypes to full-scale production.

- Customer-Centric Approach: Our Customer Support team excels in translating client needs into actionable plans, ensuring seamless communication and successful project execution.

- Quality Assurance: We empower every employee to act as a Quality Control expert in their department and perform regular training sessions. Our Quality Assurance team establishes and maintains our procedures to comply with ITAR, ISO9001:2015, AS9100D, and RoHS certifications.

Innovating the Future of Modern Manufacturing

Precision sheet metal parts are driving innovation in modern manufacturing by enabling the creation of highly accurate, durable, and customizable components for cutting-edge technologies.

With advancements in fabrication techniques such as CNC machining and advanced finishing processes, these parts ensure superior performance across industries like aerospace, medical, and electronics. Their versatility and ability to meet stringent quality standards make them a critical part of next-generation systems, from lightweight aerospace structures to intricate medical devices, paving the way for a more efficient and sustainable manufacturing future.

Pinnacle Precision’s dedication to excellence and advanced manufacturing capabilities make us a trusted partner for all your metal fabrication needs. Providing a new level of precision, we stand ready to partner, perfect, and deliver durable, reliable, and precision sheet metal parts, components, and assemblies.

With our team-forward approach and commitment to achieving solutions that exceed expectations, we stand ready to help your business achieve its goals.

We’re ready to handle your most challenging ask. Contact our team or request a quote and experience the Pinnacle difference for yourself today.