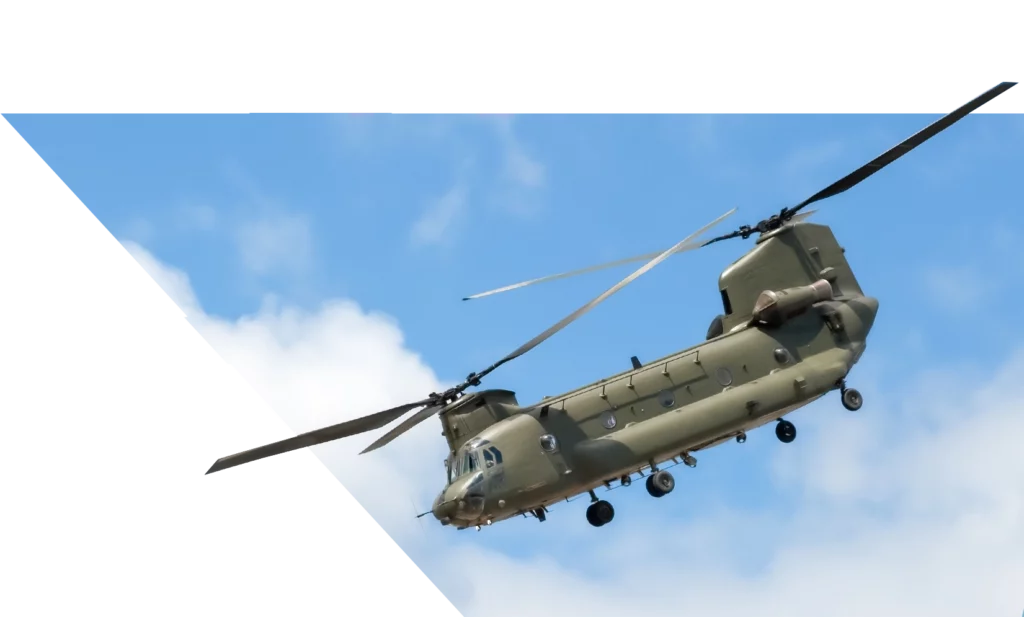

Precision sheet metal components play a critical role in the military and defense industry, ensuring the success of missions, the safety of personnel, and the reliability of equipment.

From aircraft panels to weapon system enclosures, these components must be able to perform in the harshest environments and most demanding operational conditions, all while meeting incredibly strict military standards.

Pinnacle Precision is a trusted leader in precision metal manufacturing, delivering mission-critical parts, components, and assemblies to defense manufacturers. Our expertise in fabrication, machining, and quality control allows us to produce custom, high-performance sheet metal components that comply with stringent military standards (MIL-SPEC), ensuring operational success in combat zones, military bases, and defense operations worldwide.

This article explores the vital role of precision sheet metal in military applications, its critical uses, the importance of compliance, and how Pinnacle Precision is the trusted partner for customized, durable, and military-compliant solutions.

Applications of Precision Sheet Metal in Defense

Precision sheet metal parts are relied on for an extensive range of military and defense applications, providing the structural integrity, shielding, and protection required for mission-critical systems.

With such diverse applications, precision sheet metal fabricators like Pinnacle are essential for crafting the custom components that strengthen military hardware and ensure operational success.

These components are essential in areas such as:

1. Aircraft Panels and Structural Supports

Military aircraft, including fighter jets, transport planes, and reconnaissance drones, rely on lightweight yet durable sheet metal parts for:

- Structural reinforcements that withstand extreme speeds and temperatures.

- Aircraft skin panels that provide aerodynamic efficiency and protective shielding.

- Engine and exhaust components are designed for heat resistance and durability.

2. Weapon System Enclosures and Mounts

Weapons and defense systems require precision metal enclosures to:

- Protect sensitive electronic components from dust, moisture, and shock.

- House fire control systems and targeting mechanisms.

- Provide secure mounting solutions for machine guns, missile launchers, and turret systems.

3. Vehicle Armor and Chassis Components

Military land vehicles, such as tanks, armored personnel carriers (APCs), and utility trucks, rely on sheet metal fabrication for:

- Ballistic armor panels that provide protection against enemy fire.

- Custom chassis reinforcements to improve vehicle durability and maneuverability.

- Heat shielding and ventilation systems to enhance engine performance in combat zones.

4. Communication Device Housings

Military-grade radio systems, satellite equipment, and radar units require custom sheet metal enclosures to:

- Shield sensitive electronic circuits from EMI (Electromagnetic Interference).

- Protect critical communication equipment from physical damage and environmental factors.

- Ensure seamless connectivity between command units and frontline forces.

5. Shielding and Protective Covers

Military operations depend on precision-engineered shielding solutions to:

- Minimize electromagnetic interference in radar and navigation systems.

- Protect high-voltage power systems from short circuits and external disruptions.

- Reinforce blast-resistant structures in military installations and bunkers.

The Importance of Durability and Reliability in Military and Defense

From desert battlefields to arctic operations, military equipment must perform in even the most extreme environments. With equipment breakdown or malfunction having the potential for catastrophic consequences, the reliability and durability of the components that power them are non-negotiable.

Why Sheet Metal is Ideal for Defense Applications

✔ High Strength-to-Weight Ratio – Sheet metal provides maximum durability while reducing overall weight, improving fuel efficiency and mobility in military vehicles and aircraft.

✔ Corrosion Resistance – Specialized coatings and finishes ensure that military components can withstand harsh weather, chemical exposure, and prolonged use.

✔ Impact and Heat Resistance – Military-grade alloys are engineered to resist ballistic impacts, extreme heat, and heavy mechanical stress, ensuring long-term performance.

At Pinnacle Precision, we manufacture mission-critical components designed to withstand extreme operational conditions, providing long-lasting reliability in high-stakes environments.

Meeting Stringent Military Standards (MIL-SPEC)

Military components must comply with MIL-SPEC regulations, which govern:

- Material selection for durability and operational efficiency.

- Precision tolerances to ensure seamless compatibility with other defense systems.

- Corrosion and wear resistance for long-term performance in extreme environments.

Pinnacle Precision’s Commitment to Compliance

Here at Pinnacle, we aim to exceed industry standards and customer expectations while delivering essential parts at just the right time. By maintaining strict adherence to military regulations, we confidently deliver components that meet mission-critical demands with unmatched precision.

Our commitment to quality includes:

AS9100-Certified Manufacturing – Our facility adheres to aerospace and defense quality management standards, ensuring exceptional precision and reliability.

Full Compliance with MIL-SPEC Requirements – We fabricate custom sheet metal parts that meet the highest military specifications, ensuring seamless integration with defense systems.

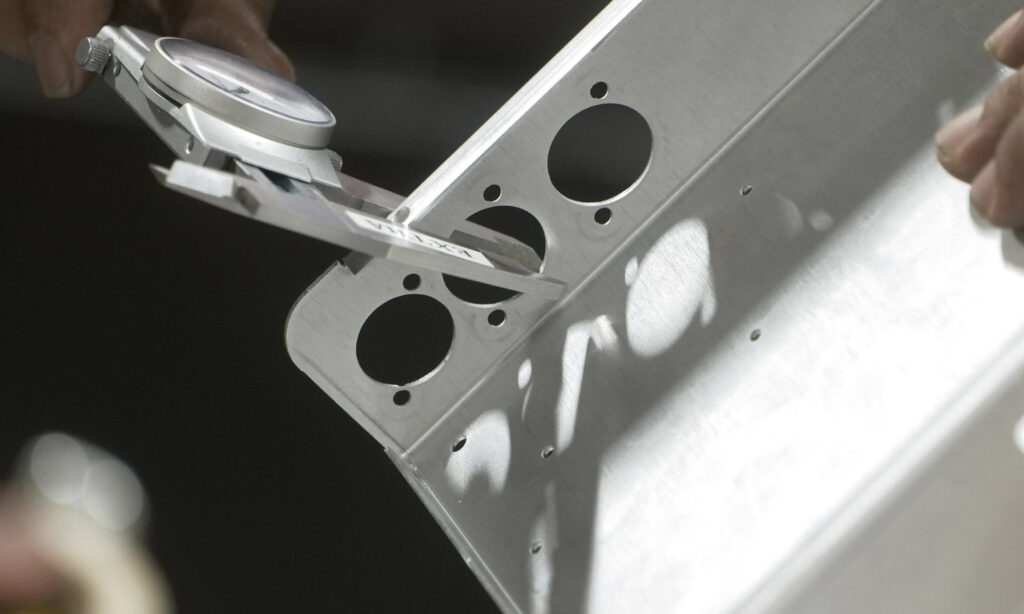

Rigorous Quality Assurance – Every component undergoes extensive testing, inspection, and validation to guarantee superior performance.

Customization and Versatility for Defense Applications

With the need to constantly adapt to evolving threats, you need to work with a flexible and versatile manufacturer who can deliver custom solutions for complex military and defense projects.

Some common custom defense applications include:

Custom enclosures for radar systems – Engineered to reduce interference and improve signal clarity.

Specialized mounting brackets for armored vehicles – Designed to enhance structural integrity and ease of maintenance.

Electromagnetic shielding for classified communication equipment – Ensuring data security in sensitive operations.

Pinnacle Precision is a leader in custom sheet metal solutions tailored to the unique requirements of complex defense applications. We work with a range of specialized materials like titanium, stainless steel, and aluminum alloys, delivering mission-ready solutions with advanced coatings and finishes.

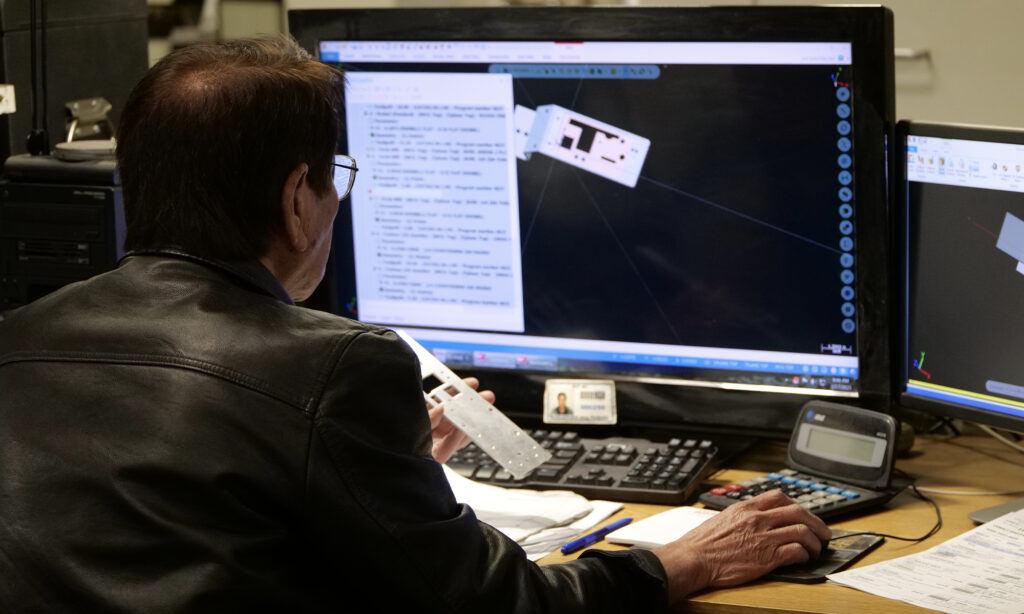

Pinnacle’s Precision Machining for the Defense Industry

Pinnacle’s team of engineers, fabricators, and quality assurance professionals leverage cutting-edge technology and advanced manufacturing techniques to produce high-precision metal components for a variety of critical military applications.

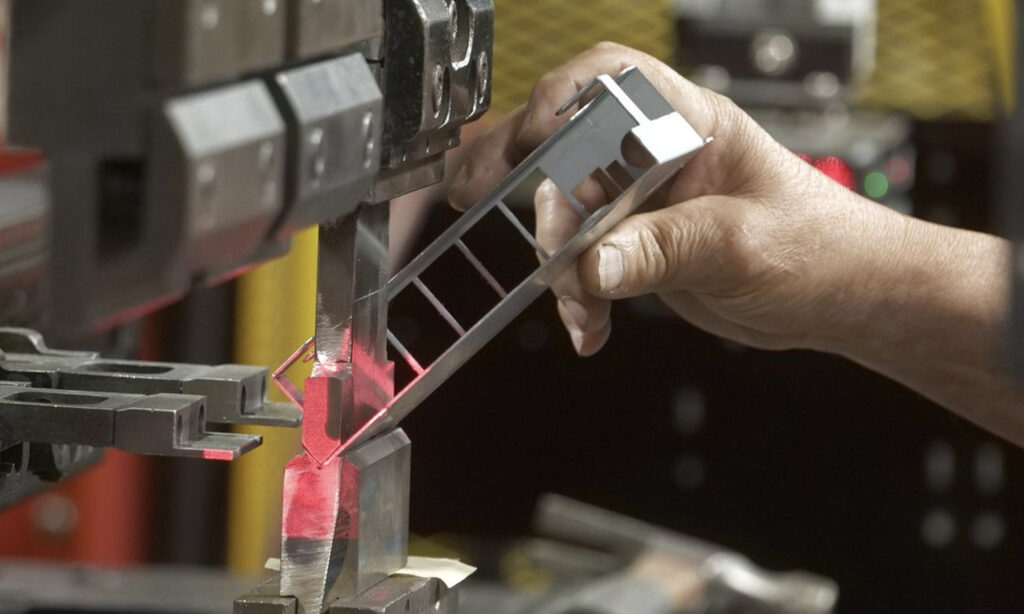

Our advanced capabilities include:

Computer Numerical Control (CNC Machining) – Ensures tight tolerances and intricate designs for mission-critical defense parts, producing components in various shapes while meeting exacting specifications required for high-performance military applications.

Laser Cutting – Delivers high-precision cuts for complex geometries and custom components for critical military applications.

Automated Forming & Fabrication – Provides efficient production without compromising quality and accuracy, with additional finishing options such as powder coating to enhance durability and corrosion resistance for military and defense applications.

Total Assembly & Quality Control – With advanced assembly capabilities, every component undergoes rigorous testing and validation to ensure the production of high-quality parts that meet the stringent requirements of military and defense applications before deployment.

Why Choose Pinnacle for Military and Defense Applications?

✔ Decades of Experience in Military Manufacturing

✔ Custom Engineering Solutions for Defense Clients

✔ Military-Grade Materials & Compliance Expertise

✔ Unparalleled Precision and Quality Assurance

Your Trusted Partner for Mission-Critical Manufacturing

Precision sheet metal components are the backbone of military and defense applications, enabling superior durability, performance, and compliance in mission-critical systems. When component malfunction can lead to mission failure, you need the confidence of knowing you’re working with a manufacturer whose components will perform under even the most demanding operating conditions.

Delivering a new level of precision, Pinnacle Precision has become the trusted partner for military and defense clients wanting durable, reliable, and precision sheet metal parts, components, and assemblies. Offering cutting-edge fabrication, rigorous quality control, and custom engineering solutions, we ensure that every component meets the highest military standards, supporting mission success in the toughest environments.

If you’re looking for a trusted partner in precision military sheet metal fabrication, the team at Pinnacle is ready, willing, and able to do our part for defense customers.

Advantages of Precision Sheet Metal Parts

Delivering numerous advantages over traditionally machined parts, precision sheet metal parts have become the preferred choice for some of the world’s leading industries.

The main advantages of precision machined parts include:

Versatility

Precision sheet metal can be fabricated into an extensive range of shapes and designs, making them perfect for various applications and requirements.

Cost-Effectiveness

Advanced manufacturing processes minimize waste and reduce production costs, making precision sheet metal parts an economical solution for both small and large-scale projects.

Durability and Strength

These components are designed to withstand harsh environments and demanding conditions, ensuring long-term performance.

Customization

Precision sheet metal parts can be tailored to meet specific design and functional requirements, allowing manufacturers to achieve unique solutions for complex challenges.

Improved Efficiency

With their high accuracy and compatibility, precision sheet metal parts contribute to smoother assembly processes and enhanced overall efficiency.

The team at Pinnacle are experts in precision sheet metal fabrication. Our expert team utilizes the latest CNC technology and decades of experience to support our customers with sheet metal fabrication, machining, finishing, total assembly, and quality assurance expertise.

The Critical Role of Material Selection in Precision Metal Fabrication

Material selection is a pivotal aspect of precision sheet metal manufacturing, with the choice of materials directly impacting the performance, weight, durability, and corrosion resistance of the final product.

Common materials include:

- Steel: Renowned for its strength and durability, steel (both stainless and cold-rolled steel) is ideal for applications requiring high structural integrity.

- Aluminum: Lightweight and corrosion-resistant, aluminum is a popular choice for aerospace and electronics industries.

- Copper: Known for its excellent conductivity, copper is often used in electrical applications.

Selecting the right material ensures that components meet the specific needs of their intended applications, optimizing performance and longevity.

The trusted team at Pinnacle are masters of material selection. Our crews work with product sizes ranging from inches to yards, a broad range of sheet metal alloys and finishes, and run from prototype to production.

Pinnacle Precision’s Expertise in Precision Sheet Metal Fabrication

Pinnacle Precision is a trusted name in precision sheet metal manufacturing, producing parts for some of the world’s most advanced industries.

We set the standard in precision CNC machining, finishing, and total assembly, offering end-to-end solutions for the most demanding industries. With advanced capabilities such as fiber laser cutting and computer numerical control (CNC) technology, we deliver unparalleled accuracy and efficiency for even the most intricate designs. Our in-house powder coating services ensure a durable, high-quality finish, providing a complete manufacturing solution tailored to your exact specifications.

Our commitment to excellence is evident in every aspect of our operations.

- State-of-the-Art Facilities: Our 73,000-square-foot production floor houses CNC-powered laser cutting machines, dozens of press brakes (50- to 125-ton capability), and dedicated welding and grinding spaces.

- Unmatched Expertise: Our Technical, Production, and Quality Assurance teams bring decades of experience to every project, ensuring superior results.

- Customized Solutions: We work with a broad range of sheet metal alloys and finishes, delivering tailored solutions for runs ranging from prototypes to full-scale production.

- Customer-Centric Approach: Our Customer Support team excels in translating client needs into actionable plans, ensuring seamless communication and successful project execution.

- Quality Assurance: We empower every employee to act as a Quality Control expert in their department and perform regular training sessions. Our Quality Assurance team establishes and maintains our procedures to comply with ITAR, ISO9001:2015, AS9100D, and RoHS certifications.

Innovating the Future of Modern Manufacturing

Precision sheet metal parts are driving innovation in modern manufacturing by enabling the creation of highly accurate, durable, and customizable components for cutting-edge technologies.

With advancements in fabrication techniques such as CNC machining and advanced finishing processes, these parts ensure superior performance across industries like aerospace, medical, and electronics. Their versatility and ability to meet stringent quality standards make them a critical part of next-generation systems, from lightweight aerospace structures to intricate medical devices, paving the way for a more efficient and sustainable manufacturing future.

Pinnacle Precision’s dedication to excellence and advanced manufacturing capabilities make us a trusted partner for all your metal fabrication needs. Providing a new level of precision, we stand ready to partner, perfect, and deliver durable, reliable, and precision sheet metal parts, components, and assemblies.

With our team-forward approach and commitment to achieving solutions that exceed expectations, we stand ready to help your business achieve its goals.

We’re ready to handle your most challenging ask. Contact our team or request a quote and experience the Pinnacle difference for yourself today.